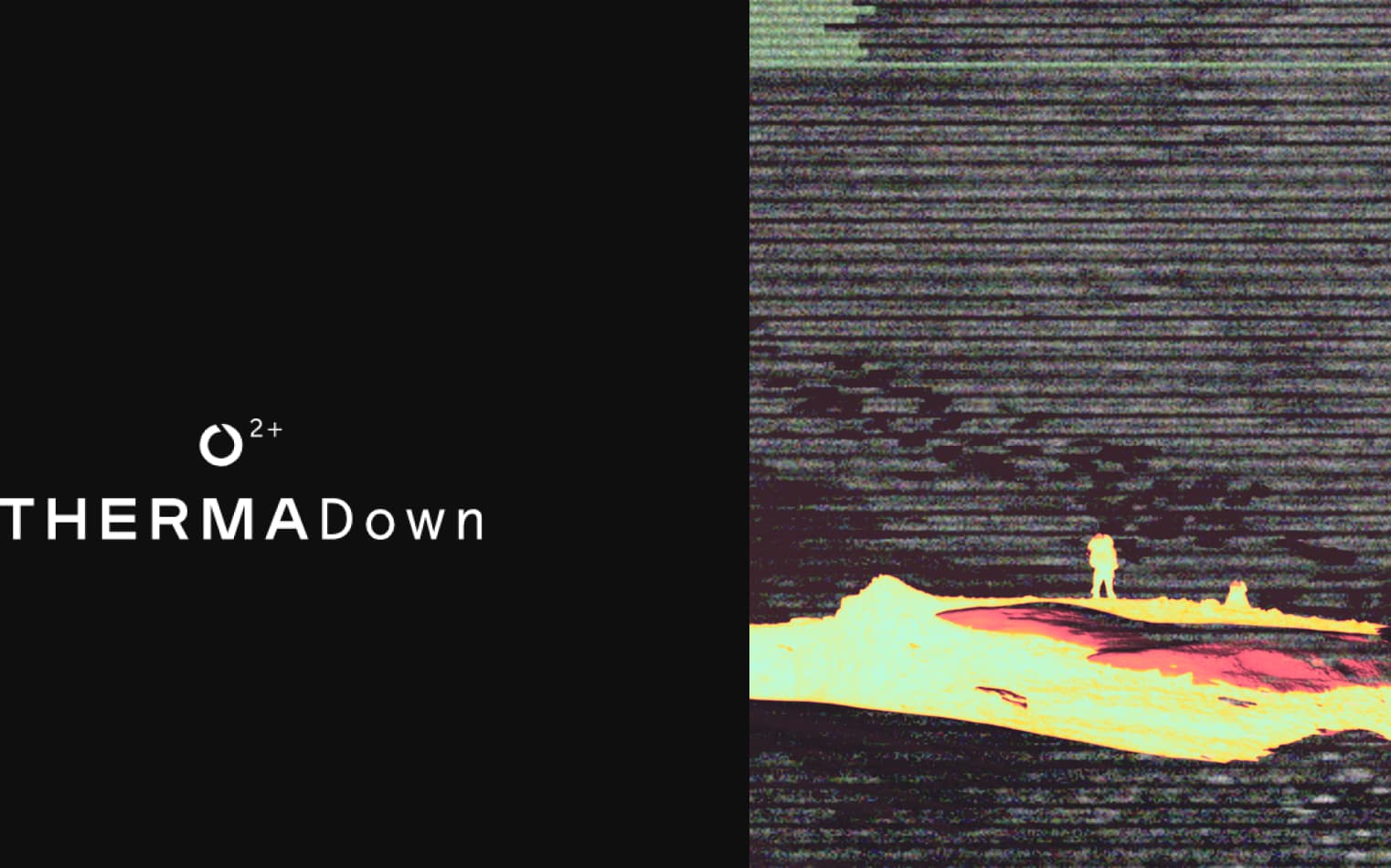

It’s about time your insulation works as hard as you do.

Most insulations can be greatly affected by sudden shifts in the external environment — either overheating when the temperature rises or taking time to warm in sudden drops of temperature.

“Active” insulations have recently become highly sought after, but most “active” insulations on the market do not perform based on the conditions of the exertion and environment, but are technically “static” insulations meant for active experiences.

Adding infrared reflectivity to the down cluster helps create an insulation that is actively changing in tune with both the wearer and the environment. In our newly developed ThermaDown 02+, as we expend energy from our bodies, it is reflected and returned; and as the external environment changes, excess energy can be reflected to keep from overheating quickly.

Down already has a significantly wider comfort range than synthetic alternatives. ThermaDownO2+ utilizes this range of comfort and down’s ability to warm with minimal weight and combines it with a patent pending technology that coats the down with tiny reflective platelets to provide a full-spectrum infrared reflectivity.

We are essentially combining the efficiency of natural down with the benefits of a space blanket.

As heat from the body is reflected off the platelets, it is converted into energy in an infrared spectrum. This energy interacts with our vascular system and helps us feel warmer and brings more oxygen to our muscles through increased microcirculation. This is why metallic space blankets are so effective for trauma situations. Infrared blankets are also used to help increase circulation in diabetic patients.

ThermaDown allows for greater warmth with less weight, increased thermoregulation, and potential faster recovery through the reflection of energy in this infrared spectrum, creating a truly active insulation that works as hard as you do.